Nanodiamond is Everywhere Saving Lives

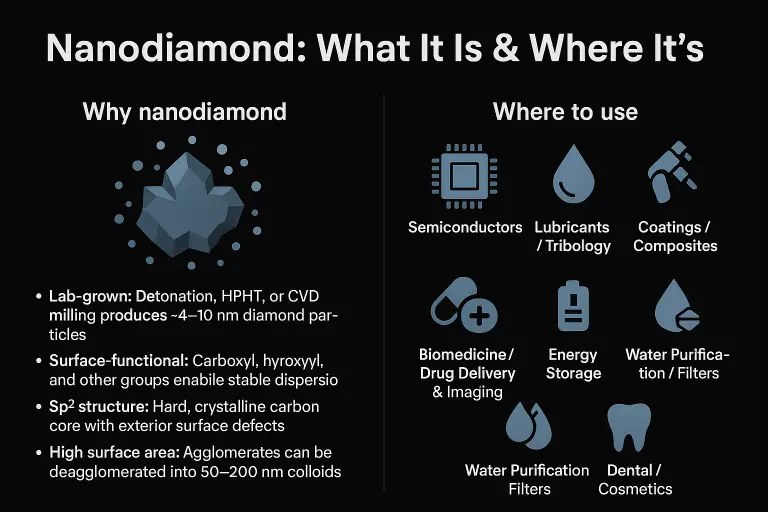

Nanodiamond (ND) refers to diamond crystals in the nanoscale—typically 4–10 nm primary particles that often form soft agglomerates tens to hundreds of nanometers across. Whether produced by detonation synthesis, HPHT milling, laser ablation, or top‑down milling of CVD diamond, the result is an sp³‑bonded carbon core with a tunable surface. Post‑processing (acid cleaning, annealing, plasma treatment) decorates that surface with carboxyl, hydroxyl, amine and other groups, enabling stable water‑ or solvent‑based colloids and strong bonding to metals, ceramics, polymers, and biomolecules. This combination—extreme hardness, chemical/thermal stability, biocompatibility, high surface area, and the ability to host quantum defects (NV centers)—lets nanodiamond act as a polishing abrasive, tribological additive, thermal/UV‑stable filler, drug or gene carrier, and even a room‑temperature quantum probe. Because it is electrically insulating yet thermally resilient, ND integrates easily with electronics, optics, coatings, and biomedical systems without introducing conductivity or rapid degradation.

How nanodiamond is used

Surface finishing & CMP: Ultra‑flat polishing of Si, SiC, GaN, sapphire, and optics; scratch‑resistant finishing of cutting tools and watch components.

Lubricants & tribology: Additive in oils/greases and cutting fluids to reduce friction and wear; boundary films form on metal to extend tool and gearbox life.

Coatings & composites: Reinforcement in epoxies, PEEK, PTFE, and electroplated Ni/Co—improves hardness, modulus, abrasion resistance, and thermal stability.

Thermal management: Filler in thermal greases and polymers for improved conductivity with electrical insulation.

Energy storage: Conductive/robust binders and interlayers in Li‑ion/Li‑metal batteries; additives in supercapacitor and fuel‑cell electrodes.

Water treatment & membranes: ND‑modified surfaces resist fouling and enhance filtration, adsorption, and antimicrobial performance.

Biomedical & life sciences: Drug/gene delivery (ligand‑functionalized ND), scaffolds and dental composites, bio‑imaging and nanoscale thermometry/magnetometry via NV‑center nanodiamonds.

Dental & cosmetics: High‑gloss polishing pastes, enamel repair/occlusion aids in some toothpastes, light‑scattering pigments in premium skincare.

Sensors & analytics: ND hosts color centers (NV, SiV) for quantum magnetometry/thermometry in fluids and near cells; fluorescent ND as robust bio‑labels.

Industries & example products

Semiconductors & optics: CMP slurries, sapphire/GaN polishers, scratch‑resistant optical coatings.

Aerospace/automotive & industrial: Anti‑wear lubricants, reinforced epoxies and plating for gears, bearings, and pumps.

Electronics & power: Thermal interface materials (pads/greases), potting compounds, EMI‑safe heat‑spreader composites.

Energy & environment: Battery binders/interlayers, fuel‑cell electrodes, filtration media and membranes.

Medical & dental: Composite resins, polishing pastes, imaging tracers, targeted‑delivery particles.

Consumer goods & cosmetics: High‑sheen polishes, durable coatings, skincare formulations.