Hardware in Harsh Environments on Earth & Beyond will Function Better, Last Longer, Cost Less with Grown Diamond

Image Credits: NASA

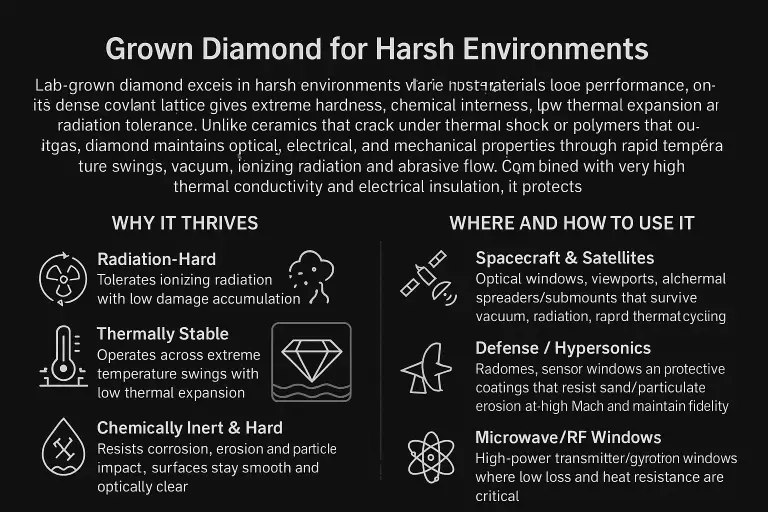

Lab‑grown diamond excels where conventional materials struggle: vacuum, ionizing radiation, abrasive particles, corrosive media, and violent thermal cycling. Its stiff, tightly bonded lattice yields extreme hardness, chemical inertness, and very low thermal expansion, so parts stay dimensionally stable and optically clear even as temperatures swing or particles strike at high speed. Because diamond also conducts heat exceptionally well while remaining electrically insulating, it protects sensitive sensors, optics, and electronics—pulling heat away, resisting erosion and corrosion, and preserving alignment and signal quality over long missions.

In practice, these properties translate into higher power handling, lower drift, and slower degradation. Windows stay transparent; RF components keep their low loss; detectors maintain calibration; and packages survive repeated shock and temperature cycles. The result is hardware that functions better, lasts longer, and fails less in mission‑critical environments.

Why it thrives

Radiation‑hard: Tolerates ionizing radiation with low damage accumulation; maintains optical/electrical performance.

Thermally stable: Low coefficient of thermal expansion; survives rapid temperature swings and thermal shock.

Chemically inert & superhard: Resists corrosion, oxidation, abrasion, and particle impact; surfaces remain smooth and clear.

Broad‑band transparency & low RF loss: Transmits UV→IR; handles high RF/microwave flux with minimal heating.

Where and how to use it

Spacecraft & satellites: Optical windows, viewports, and thermal spreaders/submounts that endure vacuum, radiation, and fast thermal cycling.

Defense / hypersonics: Radomes, sensor windows, and protective coatings that resist sand/particulate erosion at high Mach while preserving signal fidelity.

Microwave/RF systems: High‑power transmitter/gyrotron windows and output couplers where low insertion loss, high heat tolerance, and mechanical strength are critical.

Nuclear/particle environments: Diamond radiation detectors, beam monitors, and diagnostics windows that keep low leakage and stable calibration.

Aerospace/industrial extremes: Wear surfaces, viewports, and submounts in hot, corrosive, or abrasive tools; downhole or engine‑bay electronics that need thermal and mechanical robustness.

What improves

Functionality: Higher power throughput, stable optics/RF response, lower sensor noise, tighter alignment.

Longevity: Greater resistance to erosion, corrosion, and radiation damage extends service intervals and reduces replacements.

Safety & reliability: Cooler, tougher assemblies with fewer failure modes in critical operations.