Grown Diamond May Have Stopped this From Happening

Lab‑grown diamond is one of the most effective solid materials for moving heat. Its room‑temperature thermal conductivity can reach ~1,000–2,000 W/m·K—several times higher than copper or aluminum—so heat flows through diamond with exceptionally low resistance. Unlike metals, diamond is also an electrical insulator (wide bandgap ~5.5 eV), which means it can be placed in intimate contact with circuits to pull heat away without introducing electrical shorts. Its low thermal expansion and high stiffness help maintain flatness under load, preserving good contact to adjoining layers. Together, these traits make grown diamond an outstanding heat spreader: it can take a concentrated heat source, rapidly distribute the heat laterally, and lower peak (“hot spot”) temperatures.

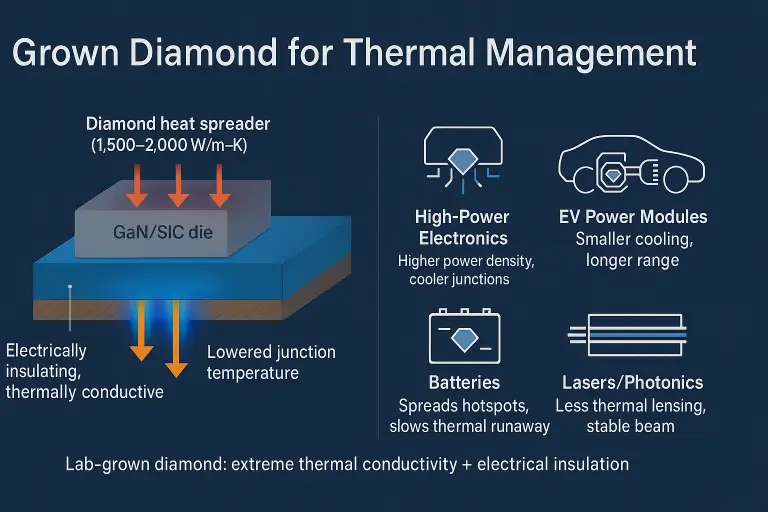

How diamond manages heat and spreads it

Heat spreading: A thin CVD diamond plate or film bonded above or below a die spreads heat laterally before it enters a heat sink, reducing junction temperatures and temperature gradients that drive failure.

Thermal interface enhancement: Metallized diamond surfaces (e.g., Ti/Pt/Au) can form low‑resistance bonds to copper, SiC, GaN, or AlN, creating composite stacks with very high in‑plane conductivity.

Weight and size savings: Because diamond conducts heat so well, designers can meet thermal targets with thinner, lighter packages.

Demonstrations in key applications

High‑power electronics (GaN/SiC): Diamond submounts under RF power amplifiers or power MOSFETs spread heat away from active regions, enabling higher power density, longer mean‑time‑to‑failure, or operation without derating in hot environments.

Electric‑vehicle inverters and onboard chargers: Integrating diamond plates in power modules improves thermal headroom, supporting faster switching and smaller cooling systems, which can increase efficiency and range.

Batteries and battery safety: Diamond films or composite sheets placed near cell tabs, busbars, or between cells conduct heat away from local hot spots, helping keep packs more isothermal and slowing the conditions that can lead to thermal runaway.

Lasers and photonics: Diamond heat spreaders mounted to diode stacks or nonlinear crystals dissipate waste heat quickly, reducing thermal lensing and maintaining beam quality at high power.

In short, grown diamond’s unique combination of extreme thermal conductivity and electrical insulation makes it a compact, lightweight, and robust solution for thermal management across demanding systems.